This ongoing project is aimed at organizing the critical mass of electronic components rapidly overflowing onto all surfaces of my workspace.

I previously organized components by project: each batch of parts for a project was stored in their static bags in the cardboard box they arrived in. I later switched to a plastic drawer cabinet. When that cabinet filled, it was back to cardboard boxes, then fishing tackle boxes, then more cardboard boxes…

I eventually had no idea what parts I had or how many. I’d order resistors from Digikey just to find 3 identical bags of them downstairs. Into a cardboard project box they’d go, which I’d gingerly stack on top of 2 similar boxes.

ENOUGH!

I’ve seen other hobbyists use binders to organize their components and that seems to provide a high-density, low-size, easily-navigable solution, so I’m going with that.

I started with all the smaller surface mount components: transistors, resistors, MOSFETs and IC’s.

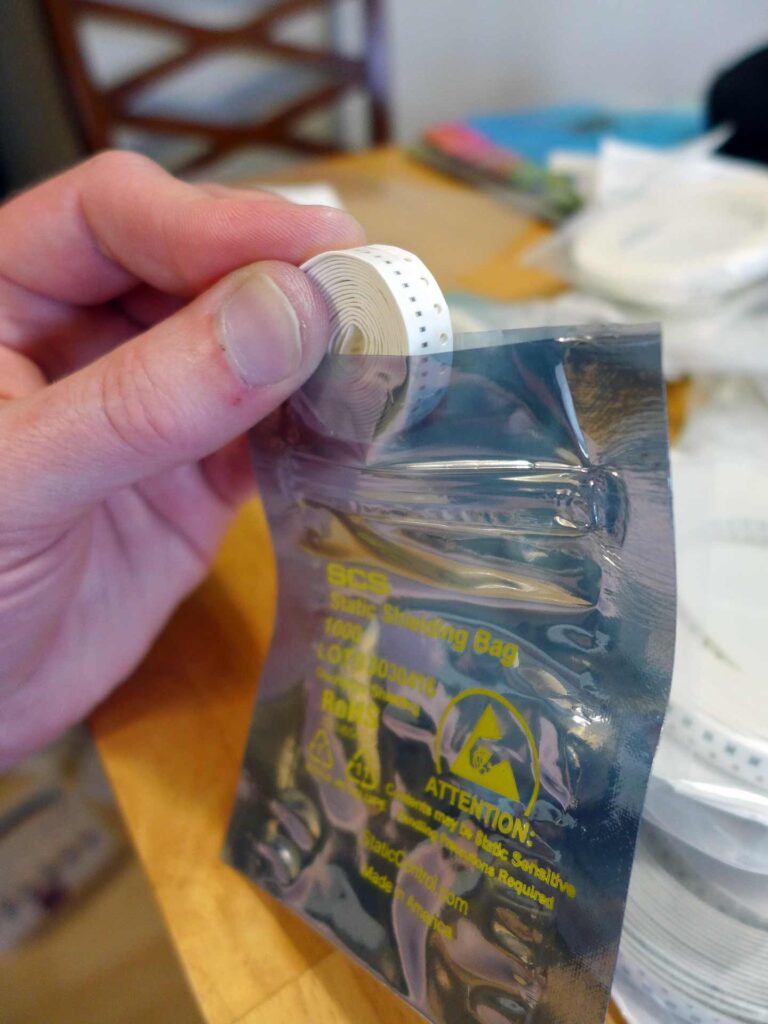

Once all the tiny SMT components were nestled in their static bags, I moved on to any small-ish reels of components. If they could still fit in a folded anti-static bag, they went into one. A lot of the reels needed re-wound by hand to tighten them up.

Finally, the large reels of components with 1000+ pcs. These were far too large for the business card sheets, so plastic trading card sheets were used instead.

The 5″ binders proved necessary – some of the plastic sheets are quite thick. They are still quite easy to navigate and parts are very easily identifiable by their stickers.

The end result is fantastic. I started out with…

- 11 medium-sized cardboard boxes full of static bags

- 3 fishing line reel boxes full of resistors

- 4 large drawer cabinets

… and finished with two 5″ binders that sit neatly in less than 1 sq.ft. on my workbench.

It’s a great start to organizing my workspace and I’m very satisfied with the result. I’m far from done though, so check back later!